WEEK 6 - NETWORKING

7 APRIL 2018

Preliminary diagram establishing connections between current practitioners and researchers. (Names and institutions have been removed for privacy reasons).

An underlying concern that I have had since the commencement of my research has been the fact that I am undertaking a topic that's main component is in a field I am unfamiliar with. In order for me to have my questions answered I have made a strong effort to try and get in touch with practitioners and educators in the field of shape memory polymers. Currently, my top three questions are:

- Is there a polymer commercially available that displays two-way shape memory characteristics?

- What is the process required for training these polymers to memorise shape?

- What facilities do I need in order to undertake this training process?

I realise that people (in general) are time-poor and that helping me in my research may not be a priority, therefore I have also been looking into open-access information and groups that have formed with the intention of sharing information. An example of such a group is Kobakant, an art collective founded by Hannah Perner-Wilson, for details visit: http://www.kobakant.at/. Hannah's work using smart materials in textile design was inspirational for me and led me to my undertaking of this area of research at the end of last year.

WEEK 7 - CONCEPT DESIGN

14 APRIL 2018

Now... how to get the light glowing...

After completing my literature review and following on with further research on shape memory polymers, I feel that my understanding of the science behind this material has increased to a level where I now understand how to manipulate for my intended designs. The next step is to develop designs that showcase this unusual material’s abilities. This is the point at which I now feel a little stuck. I have been thinking about why my designs aren’t progressing as quickly as they have in the previous years of this course and my conclusion is that the lack of a predetermined, well refined brief hasn’t been simply put in front of me. It is now up to me to set the brief, the guidelines, the restrictions and a description of the desired outcome. While I am keen to do this, the pressure of producing work that is of quality and displays a full year’s worth of work is a challenge I haven’t faced before. I have become used to a quick project turn around, projects that demand intense periods of design and production with a similarly quick review and assessment. I hope I can maintain my normal, consistently intense work ethic.

WEEK 8 - RESEARCH PROPOSAL

21 APRIL 2018

Initial draft of my video storyboard consisting of a combination of short clips and narration amongst footage of me speaking directly to the camera.

This week I have been working on my Research Proposal. From what I have been reviewing, this assignment appears to be a great way of planning the work for the year ahead as well as making my research intentions clear (not only to others but to myself). The section outlining our research methods and methodologies has me a little confused as, at this stage, I am unsure of what is expected. I have been undertaking the readings and watching the lectures but feel that this topic could end up a little like a rabbit hole. I feel the best way to proceed is to simply state the methodologies I intend to use and clearly outline, step by step, the methods I intend to employ. This has also made me begin thinking about the method I will use when testing the polymer. I assume I will need to devise and undertake customised tests to discover how the materials works, ie. responds to heat and force.

In addition to my Research Proposal, I have also received an assignment outline that requires me to create a video that conveys my research intentions. I am not overly fazed by this task and have already started storyboarding my ideas.

WEEK 9 - TEST PLANNING

28 APRIL 2018

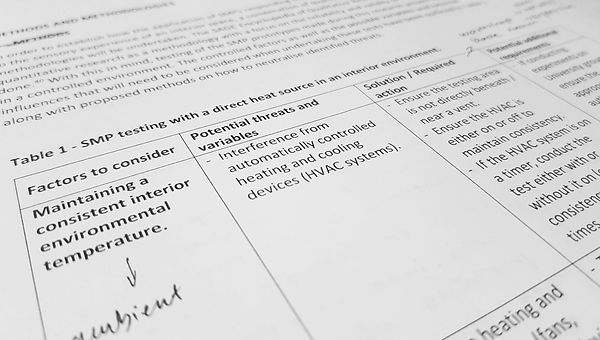

Section of my risk assessment table.

In order to best plan for the testing conditions and equipment required when testing the SMPs, I met with one of my Honours lecturers to discuss options. I am very grateful for this meeting as it helped me gain a better understanding of how to go about creating and implementing tests for research. I have now discovered that three distinct tests will need to be conducted to test the following:

TEST 1 - The exposure of the polymer to various temperatures.

TEST 2 - The thickness of the polymer and how this effects the time it takes for heat to affect the polymers’ state.

TEST 3 - Variations in the applied external force once the polymer is in its malleable state.

After planning and analysing these proposed tests, I created a table listing the possible risks / threats and solutions as well as the equipment needed. I have now realised that there may be substantial additional cost in acquiring the equipment which I hadn’t considered previously.

With these concerns in mind and in order to gain a better understanding of what is required of me to submit at mid-year break, I met with both of my Honours supervisors. We discussed my written work and the problems I have been facing with acquiring my material and the design block I have been facing. As always, we had a great discussion with great resolutions, one vital one being that I will start 3d printing models in non-SMP filament this week.